News

News

Thermomechanical Analysis of a PFC Integrating W Lattice Armour…

A new scientific paper is published by the UNITUS Nuclear Fusion Research team, concerning a thermomechanical analysis of a plasma facing component (PFC) integrating tungsten lattice armour in response to different plasma scenarios predicted in the EU-DEMO Tokamak [1].

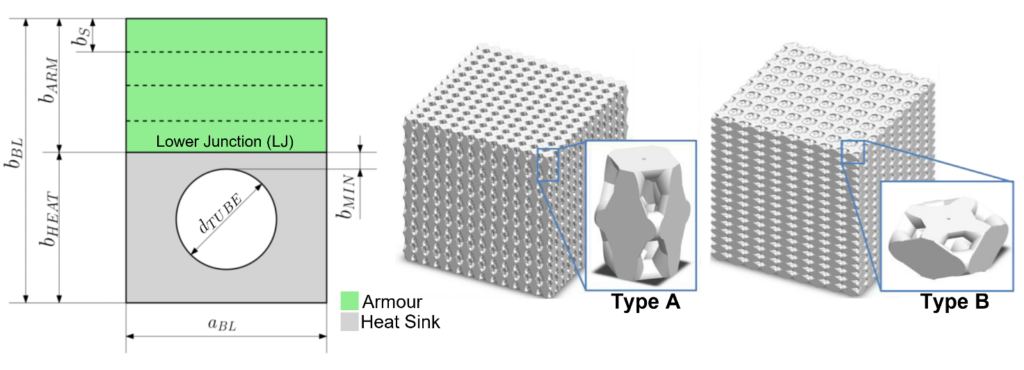

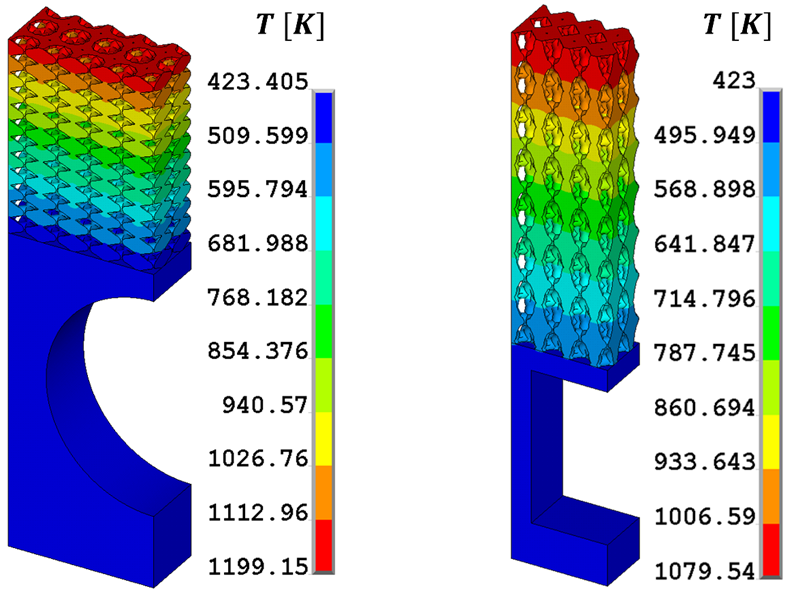

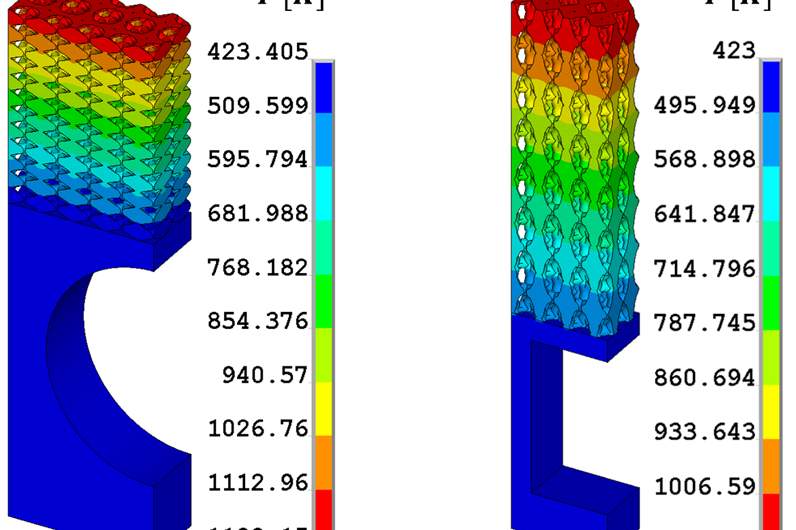

The effective and efficient management of power and particles produced within a tokamak is undoubtedly one of the fundamental steps towards the demonstration of nuclear fusion [2]. PFCs directly facing the plasma are subjected to harsh operating conditions characterised by intense thermal fluxes, erosion, neutron irradiation and sputtering phenomena, which worsen its thermos-structural resistance and deteriorate its functional integrity, ultimately [3]. The need of having sacrificial first wall limiters that are capable of mitigating the effects of such events is mandatory to provide solutions to prevent the excessive damage of the breeding blanket first wall modules in the EU-DEMO fusion reactor, in particular during harsh plasma transients. The integration of tungsten lattices into the architecture of these components can help in meeting their conflictual requirements: a proper morphology of the elementary cell combined with an optimisation of the component design can ensure the effective exhaust of nominal thermal power during normal operation and prompt vapour shielding formation during disruption when thermal decoupling between plasma and heat sink is required. Parametric analyses were conducted on the elementary cell [4] that lead to the identification of two optimised morphologies, (Types A and B). Parametric design analysis based on the use of a 2D model [5] proposed two optimised flat tile configurations in which the complexity of the geometry of the W lattice structure was simplified through a smeared approach: the first one was characterised by Type B W lattice armour, a CuCrZr heat sink and a circular cooling duct, and the second comprised Type A W lattice armour, a heat sink in EUROFER97 and a square duct. In the present work, a detailed 3D model of the two optimised component layouts was set-up, including the complex reticular geometry of the lattice structure, in order to analyse in detail the influence of the actual cellular morphology on the properties of the lattice layer and on the overall performance of the component. The 3D model allowed for performing coupled thermomechanical analyses with regard to the loading conditions that develop during different plasma scenarios and for verifying the structural integrity of the component through acceptance criteria established for ITER in-vessel components (SDC-IC). In particular, the two configurations considered in this study were able to effectively meet the requirements under normal reactor operating conditions (during which the nominal thermal load was in the order of 0.5–1.5 MW/m2 in EU-DEMO), while some requirements were missed in the ramp-down case (when transient heat flux peaks up to 4 MW/m2 were expected). However, the first HHF (high heat flux) tests are about to be performed in order to benchmark the analyses, and dedicated experimental campaigns are ongoing to evaluate the performance of similar components and to allow for a more accurate assessment of their structural integrity under the expected operating conditions [6], [7].

- Paoletti et al., “Thermomechanical Analysis of a PFC Integrating W Lattice Armour in Response to Different Plasma Scenarios Predicted in the EU-DEMO Tokamak”, Nuclear Engineering 2022, 3, 421-434;

- J. H. Donné, “The European roadmap towards fusion electricity,” in Philosophical Transactions of the Royal Society A: Mathematical, Physical and Engineering Sciences, Royal Society Publishing, Mar. 2019.

- R. Barrett et al., “Progress in the engineering design and assessment of the European DEMO first wall and divertor plasma facing components,” Fusion Engineering and Design, vol. 109, no. 111, pp. 917–924, 2016.

- de Luca et al., “Parametric design study of a substrate material for a DEMO sacrificial limiter,” Fusion Engineering and Design, vol. 158, no. May, p. 111721, 2020.

- Stefanini et al., “Parametric FE model for the thermal optimization of a Plasma Facing Component equipped with sacrificial lattice armours for First Wall limiter application in EU-DEMO fusion reactor,” 2022.

- H. You et al., “Limiters for DEMO wall protection: Initial design concepts & technology options,” Fusion Engineering and Design, vol. 174, Jan. 2022.

- Mantel et al., “Development and testing of an additively manufactured lattice for DEMO limiters,” Nuclear Fusion, vol. 62, no. 3, Mar. 2022.